CNT production system derived from

marine plastic waste

Future Earth Lab. Co., Ltd / <Co-investigator> Tokyo University of Science | Ikuno Lab.

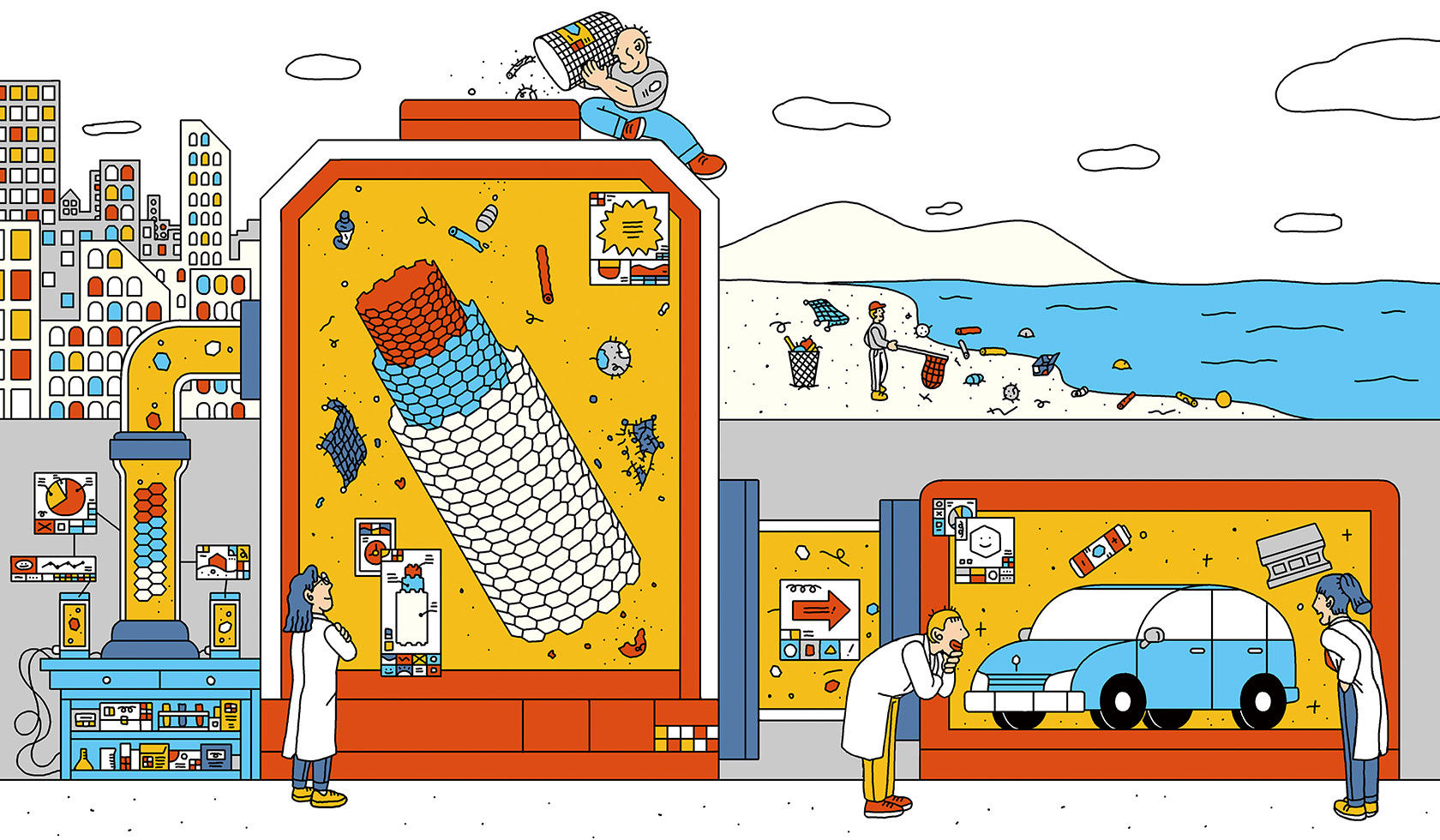

Service Vision

Upcycling marine plastic waste into carbon nanotubes (CNTs), a high value-added

functional material. By popularizing this trend, we will create a large incentive for marine litter

collection and accelerate marine litter reduction.

We will realize a new circular economy by producing CNTs derived from marine plastic waste using our

proprietary CNT conversion process and equipment, and supplying them to a wide range of fields

including the battery industry, automobile industry, and the construction industry.

Service Features

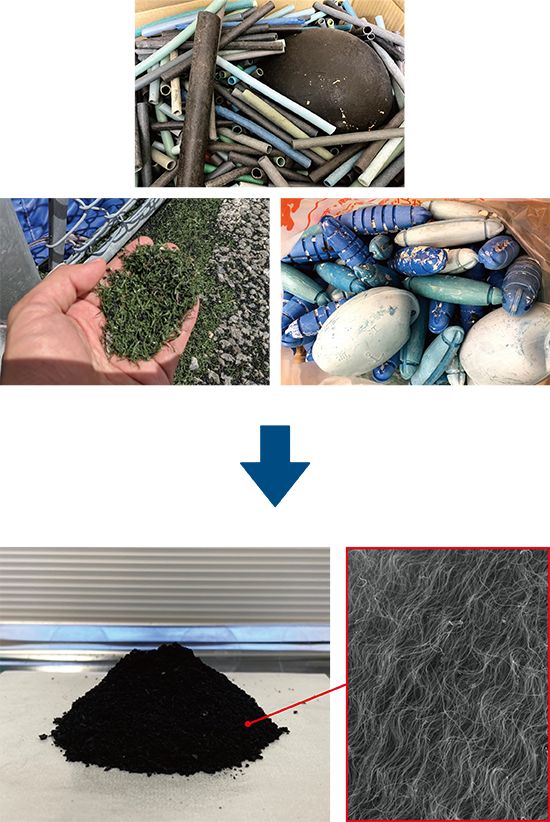

Converting plastic materials such as oyster pipes, artificial turf, and fishing nets into CNTs

Our proprietary process and equipment convert general-purpose plastic materials, similar to actual waste plastics, into CNTs at high speed and in large quantities. It has also been proven that the physical properties are equivalent to those of commercially available products.

Service Overview

Can be used for a wide variety of plastic materials

Ten types of plastic

materials are available for CNT conversion in this process, which include PE, PP, PS, PVC, and

ABS.

Almost all common waste plastic materials are covered by our technology.

High speed and high volume conversion

The CNT conversion efficiency of this process is on average 2 to 4 times higher than that of conventional CNT production methods, and depending on the feedstock material, as much as 8 times higher. The current maximum yield is 200g/day.

Physical properties equivalent to those of commercial products

Although made from marine plastic waste, the CNTs have proven to have comparable properties in terms of diameter, length, and electrical properties to commercially available multilayer CNTs made from high-purity hydrocarbon gas.

Process and schedule

REFERENCE

PRICE

Initial cost : 150,000 yen /

1,000-5,000 yen per gram of

CNT

* Please consult with us as

needed, including joint research.

* CNT prices vary depending on the type of marine litter,

availability of CNT conversion, conversion yield, and production volume.

Team

Future Earth Lab. Co., Ltd

Location: 2-2-14 Honmachi, Kokubunji-shi, Tokyo, Japan

Representative: Yuji Matsukawa, CEO

Website: https://www.future-earth.jp/

Main Business Description

●Sales and installation of environmental products.

Tokyo University of Science | Ikuno Lab.

Location: 6-3-1 Shinjyuku, Katsushika-ku, Tokyo, Japan

Representative: Takashi Ikuno, Associate Professor, Department of Electronic Systems Engineering

Website: https://www.rs.tus.ac.jp/tikuno/

Main Research

●Development of conversion technology of polymeric materials to nanocarbon materials.

●Research and development of flexible nano-devices.